Choosing the right type of door for your cleanroom is essential to maintain the integrity of your controlled environment. This decision can affect everything from contamination control to workflow efficiency. Cleanroom doors come in two primary types: single and double. Each has its own set of benefits, ideal use cases, and considerations. Let’s delve into each type to help you make an informed decision that suits your space’s specific needs.

Single vs. Double Cleanroom Doors

The distinction between single and double cleanroom doors is pivotal in designing an effective cleanroom environment. This choice not only impacts the physical layout but also affects operational efficiency, contamination control, and compliance with industry-specific regulations.

Single Cleanroom Doors

Typically, smaller cleanrooms or facilities with less foot and equipment traffic prefer single cleanroom doors. They are suitable for environments with limited space and moderate access demand. Their simplicity offers a dual advantage: cost-effectiveness and space efficiency. This makes single doors particularly appealing for operations where budgetary constraints and spatial limitations are primary concerns.

When Best Used:

· Ideal for cleanrooms within academic research facilities, small-scale pharmaceutical labs, and other technical spaces. Single cleanroom doors cater to environments with moderate operational scales. They offer an efficient solution for areas not requiring extensive access while still upholding cleanliness standards.

· Suitable for areas where cleanroom access is less frequent or involves fewer personnel and smaller equipment.

Benefits:

· Cost Savings: Single doors are less expensive to install and maintain compared to double doors. This makes the clean room doors a budget-friendly option.

· Space Conservation: They require less clearance and space for operation, an essential factor in compact cleanroom designs.

· Simplicity in Maintenance: With fewer mechanical components and sealing interfaces, single doors are easier to maintain, reducing the likelihood of operational downtime.

· Flexibility: Single doors can often be customized or adjusted with relative ease to meet changing operational needs or accommodate new equipment.

Double Cleanroom Doors

Conversely, double cleanroom doors are designed for larger cleanrooms. Or even those that necessitate stringent contamination control measures. The hallmark of double doors is their airlock functionality.

This creates an intermediate space between two environments of differing cleanliness levels. This airlock acts as a buffer zone. Significantly reducing the risk of particulate contamination from one area to another. This is crucial in maintaining the integrity of high-standard cleanrooms.

Benefits:

· Superior Contamination Control: The airlock system drastically reduces the ingress of contaminants, maintaining the cleanroom’s required cleanliness standards.

· Enhanced Traffic Flow: Clean room double doors facilitate the smooth movement of a higher volume of personnel and equipment. This prevents bottlenecks and supporting operational efficiency.

· Increased Flexibility and Scalability: The design accommodates future expansions or reconfigurations of the cleanroom layout. This offers a long-term solution that can adapt to evolving operational needs.

· Compliance with Regulatory Standards: For industries subject to strict regulatory oversight, clean room double doors can help ensure compliance with cleanliness and safety standards. This reduces the risk of costly violations.

Manual and Powered Cleanroom Doors

After picking a single or double cleanroom door, you need to choose between manual or powered operation. This decision impacts both the functionality and efficiency of your cleanroom environment.

This choice is not merely a matter of preference but hinges on several factors. These factors include operational efficiency, contamination control, and overall workflow dynamics. Both manual and powered doors have distinct advantages and ideal use scenarios. Therefore, making it important to consider which type aligns with your cleanroom’s specific requirements.

Manual Cleanroom Doors: Simplicity and Reliability

Manual doors, operated by hand, stand out for their simplicity and reliability. They are ideal for cleanrooms with lower traffic volumes where the risk of contamination from door usage is manageable. These doors excel in environments where operational demands and contamination risks are lower.

The appeal of manual doors lies in their straightforward operation and low maintenance. These are attributes that can significantly reduce the likelihood of mechanical failures and operational downtimes.

Ideal Use Cases:

· Cleanrooms in small-scale laboratories, academic research facilities, or any setting where the frequency of door usage is moderate.

· Facilities where budget constraints prioritize cost-effectiveness both in terms of initial installation and ongoing maintenance.

Key Benefits:

· Reduced Complexity: With fewer moving parts and electronic components, manual doors are less prone to breakdowns, ensuring consistent operation.

· Cost-Effectiveness: They are generally less expensive to install and maintain, offering a budget-friendly solution without compromising on cleanliness or functionality.

· Ease of Maintenance: Simplified mechanisms make manual doors easier to repair and maintain, minimizing downtime and operational disruptions.

Powered Cleanroom Doors: Automation for Efficiency

Powered doors, on the other hand, bring automation to the forefront of cleanroom operation. The clean room doors are equipped with sensors and mechanisms for automatic opening and closing. Therefore, minimizing the need for physical contact. This leads to a significant reduction in the risk of contamination.

This feature is particularly beneficial in high-traffic cleanrooms or in areas where maintaining sterility is paramount.

Ideal Use Cases:

· High-traffic cleanrooms in industries like pharmaceutical manufacturing, biotechnology, and semiconductor production where contamination control is critical.

· Facilities where operational efficiency and minimizing manual interventions are key priorities.

Key Benefits:

· Enhanced Contamination Control: By reducing the need to touch door surfaces, powered doors significantly lower the risk of contaminant spread.

· Operational Efficiency: Automatic operation facilitates smooth traffic flow, reducing bottlenecks and enhancing the overall efficiency of cleanroom operations.

· Accessibility: Powered doors can improve accessibility, providing an effortless entry and exit path for personnel, especially when carrying materials or equipment.

Making the Right Choice for Your Cleanroom

The decision on the type of cleanroom door to install should be based on a thorough assessment of your facility’s specific needs. You should consider factors such as traffic flow, space availability, contamination control requirements, and budget constraints. Here’s a brief guide to aid your decision:

· For smaller or budget-conscious cleanrooms with moderate traffic, single manual swing doors could offer a practical solution.

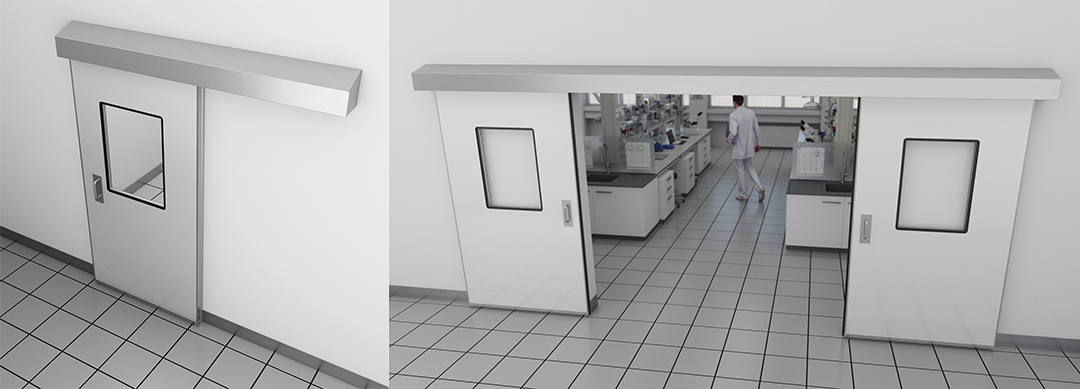

· In space-constrained environments with high traffic, sliding doors—either manual or powered—may provide the best balance of space efficiency and accessibility.

· For large cleanrooms with stringent contamination controls, double doors (swing for maximum seal integrity or sliding for space conservation) could be essential.

Ultimately, selecting the right cleanroom door involves balancing functionality, safety, efficiency, and compliance with your operational requirements. Whether you choose single or double, manual or powered, your decision should enhance your cleanroom’s performance, ensuring a clean, efficient, and compliant operation.