Maintaining the integrity of perishable goods, ensuring safety, and optimizing operational efficiency are paramount concerns in food processing. Jamison Door Company has been at the forefront of addressing these challenges with innovative solutions tailored for the food processing sector. Our extensive range of products, from high-speed doors to cold storage doors, is designed to meet the unique needs of food handling and processing facilities.

Advanced Cold Storage Solutions

Jamison Door Company’s cold storage doors are engineered to provide superior insulation and durability. This is crucial for maintaining the required temperatures in refrigerated and freezer environments. These doors help in minimizing energy consumption by preventing air leakage. As a result, contributing significantly to operational cost savings.

Our doors are made with high-quality materials. They can withstand tough conditions in food processing plants. This involves opening and closing frequently. They also encounter cleaning agents and moisture daily.

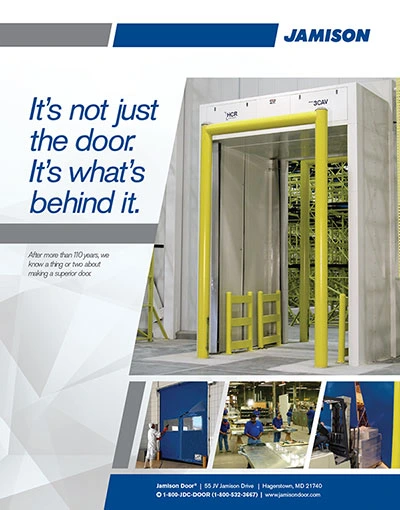

High-Speed Doors for Optimal Productivity

In fast-paced food processing environments, efficiency is key to meeting production deadlines and ensuring product freshness. Our Jamison high-speed doors facilitate smooth traffic flow of personnel and materials by opening and closing rapidly. They especially save time and energy by controlling temperature in important areas during transit. The quick operation of these doors significantly reduces the opportunity for air exchange, which is essential in preventing cross-contamination and maintaining hygienic conditions.

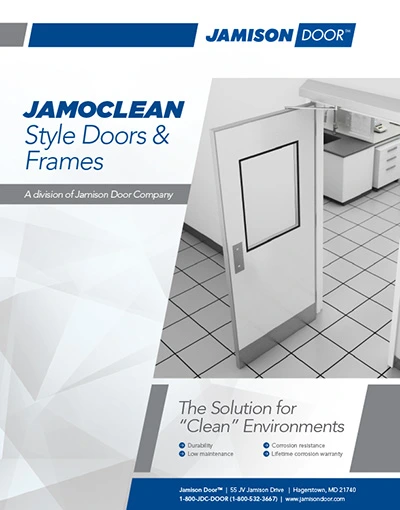

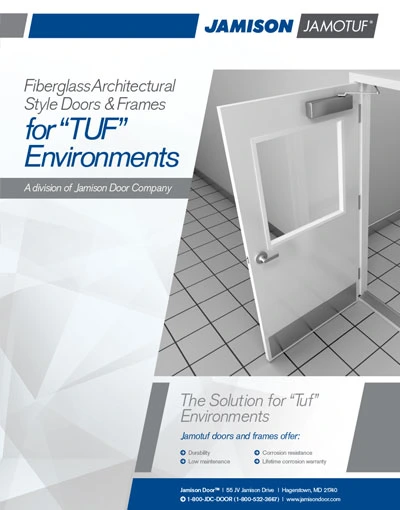

Tailored Solutions for Hygiene and Safety

Jamison Door Company makes doors for food processing that are resistant to corrosion, moisture, and harmful microbes. They stress the importance of hygiene in this industry. These doors maintain a clean and safe environment for food production. We prioritize the health and safety of our customers by providing high-quality, durable doors.

These doors are easy to clean and disinfect, supporting the industry’s stringent sanitation protocols. With safety being a paramount concern, our products come equipped with features like automated operation and safety sensors to prevent accidents and injuries among workers.

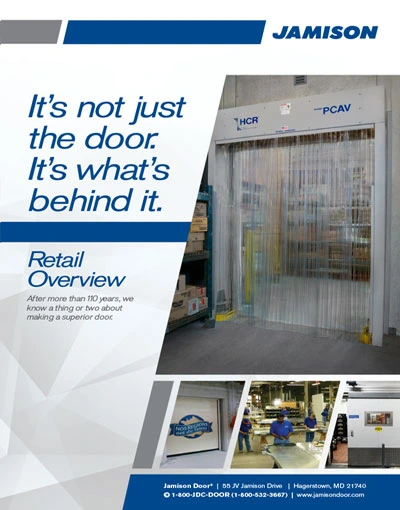

Additionally, HCR air doors are an excellent solution for enhancing hygiene and cleanliness within food processing environments, as they minimize the need for physical contact and support compliance with strict sanitation standards.

Energy Efficiency and Sustainability

In an era where sustainability is increasingly important, Jamison Door Company’s solutions contribute to energy conservation efforts. These doors help reduce the need for excessive cooling or heating by keeping environments controlled. This, in turn, lowers the carbon footprint of food processing facilities. Their durable design also means a longer life span and reduced need for replacements, contributing to waste reduction.

Jamison’s sliding cold storage doors are ideal for spaces where conservation of room and efficient use of space are priorities. These doors provide excellent sealing capabilities to prevent air infiltration and energy loss, making them highly energy-efficient. The sliding mechanism is designed for ease of use, ensuring smooth and reliable operation even in the most demanding environments, where frequent access is required.

HCR air doors stand out for their energy efficiency. They significantly reduce the loss of cooled or heated air and thereby lowering operational costs. Air doors, also known as air curtains, allow for seamless traffic flow of personnel and goods. This eliminates the delay caused by traditional physical doors and contributes to a more efficient operational process.

Maintaining Critical Environmental Conditions

HCR Air Doors offer an innovative and efficient way to maintain critical environmental conditions within food processing facilities. These air doors create a powerful and invisible barrier that separates different areas, preventing cross-contamination while maintaining temperature and humidity control. This technology ensures that the integrity of food products is preserved by minimizing the exposure to fluctuating conditions. Which is essential for food safety and quality.

For environments requiring rapid and easy access, Jamison’s swinging cold storage doors offer an effective solution. They withstand the heavy operational demands of food processing facilities, featuring durable materials that resist wear and tear. The swinging design allows for easy movement of people and items while keeping energy in and controlling temperature.

Customization and Support

Recognizing that each food processing facility has its unique challenges, Jamison prides itself on offering customized door solutions. Our team works closely with clients to assess specific needs, ensuring that the door systems integrate seamlessly with existing processes and infrastructure. Beyond providing high-quality products, Jamison Door Company offers exceptional customer support, from installation to maintenance and repair services, ensuring that their door systems continue to operate efficiently and effectively over time.

Jamison Door Company’s dedication to innovation and quality has made it a trusted partner in the food processing industry. Our door solutions are not just about maintaining temperatures or speeding up operations. They are about creating safer, more efficient, and sustainable food processing environments. As the industry continues to evolve, Jamison Door Company’s commitment to meeting its changing needs with advanced, reliable, and customized solutions is unwavering, setting a standard for excellence in food processing solutions.