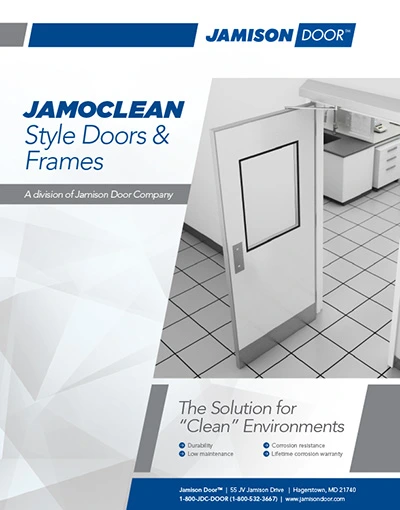

Maintaining the integrity of cleanroom environments requires careful consideration of every element, from air filtration systems to flooring materials. Doors play a critical role in controlling contamination levels and ensuring that the environment remains sterile and controlled. Jamison Door Company’s Jamoclean sliding doors offer a practical, efficient, and reliable solution for cleanroom applications.

The Role of Doors in Cleanroom Environments

Cleanrooms are specialized spaces designed to maintain extremely low levels of particulates, such as dust, airborne organisms, or vaporized particles. They are crucial in industries like pharmaceuticals, biotechnology, and electronics, where even the smallest contamination can lead to significant issues in production quality or safety.

In these environments, doors must serve multiple functions. They need to be airtight to prevent contaminants from entering, easy to clean, and durable enough to withstand the rigorous demands of a cleanroom setting. Traditional hinged doors, while common in many settings, may not always be the most practical solution for cleanrooms. This is where sliding doors, particularly Jamoclean sliding doors from Jamison, excel.

Why Choose Sliding Doors?

Sliding doors offer several advantages in a cleanroom environment:

- Space Efficiency: Unlike hinged doors, which require space to swing open, sliding doors move horizontally on a track system. This makes them ideal for areas where space is at a premium, allowing for more efficient use of the cleanroom’s interior.

- Ease of Use: Sliding doors are easier to operate, especially when designed with automatic or hands-free systems. This reduces the need for physical contact, lowering the risk of pollutants and making the environment safer for sensitive operations.

- Enhanced Airtight Sealing: Cleanrooms require stringent control over airflow to maintain sterile conditions. Sliding doors can provide an airtight seal, especially when equipped with advanced sealing technologies like those in Jamoclean doors. This helps maintain the required pressure differentials between the cleanroom and adjacent areas.

- Durability and Longevity: Cleanroom doors are subjected to frequent opening and closing, making durability a key consideration. Sliding doors, particularly those designed by Jamison, are built to withstand heavy use without compromising their functionality or seal integrity.

The Jamoclean Slide: A Closer Look

Jamison Door Company’s Jamoclean sliding doors are specifically engineered to meet the demanding requirements of cleanroom environments. Here’s what makes these doors stand out:

- Hygienic Design: Jamoclean sliding doors feature smooth surfaces and minimal crevices, making them easy to clean and disinfect. This is crucial in a cleanroom setting where every surface must be free of contaminants.

- Advanced Sealing Technology: Maintaining an airtight seal is essential in cleanrooms. Jamoclean doors feature advanced sealing systems that ensure a tight seal every time you close the door. This not only helps in maintaining cleanroom conditions but also contributes to energy efficiency by reducing air leakage.

- Energy Efficiency: Maintaining a cleanroom requires significant energy, particularly in controlling temperature and air quality. Jamoclean sliding doors contribute to energy savings by minimizing air leakage, which can help reduce the energy required to maintain the cleanroom environment. Over time, this can lead to substantial cost savings.

Unique Requirements

Cleanroom sliding doors are engineered with a seamless design fit for a variety of applications.

- Configuration Options: Jamoclean sliding doors are available in both single and double configurations, allowing you to choose the setup that best fits your cleanroom’s layout and operational needs. Depending on the needs of your facility, Jamoclean sliding doors can be operated manually or in power mode. The manual option offers a straightforward, cost-effective solution, while the power mode provides the convenience of automated operation, reducing physical contact and enhancing workflow efficiency.

- Customizable Solutions: Every cleanroom is unique, and so are its requirements. Jamison Door Company offers customizable options for their Jamoclean sliding doors, allowing businesses to choose the specific features that best meet their needs. You can tailor Jamoclean doors to fit the exact specifications of any cleanroom, whether you consider size, material, or automation features.

- Automation and Safety Features: For high-traffic cleanroom environments, automation is more than just a convenience—it’s a necessity. You can integrate Jamoclean sliding doors with automatic opening systems, including touchless sensors, to reduce the need for physical contact. Additionally, these doors come with safety features such as anti-pinch protection, ensuring that they are safe to use in fast-paced settings.

Applications of Jamoclean Sliding Doors

Jamoclean sliding doors are versatile and can be used in various cleanroom applications, including:

- Pharmaceutical and Biotechnology Facilities: Where sterility is paramount, Jamoclean doors help maintain the necessary conditions for drug production and research.

- Healthcare Settings: From hospitals to laboratories, maintaining a clean and controlled environment is critical, and Jamoclean doors provide the necessary protection.

- Chemical Plants: In environments where the containment of hazardous substances is crucial, Jamoclean doors provide a reliable barrier, ensuring that cleanroom conditions are maintained even in challenging industrial settings.

- Food Manufacturing: In the food industry, where hygiene and contamination control are critical, Jamoclean doors help maintain a clean environment, ensuring that products are safe and meet regulatory standards.

Jamison: Your Cleanroom Sliding Door Provider

In cleanroom environments, where every detail counts, Jamison Door Company’s Jamoclean sliding doors offer a practical, reliable, and efficient solution. Their space-saving design, advanced sealing technology, and customizable features make them an ideal choice for industries that demand the highest levels of cleanliness and control. By choosing Jamoclean sliding doors, businesses can ensure that their cleanroom environments remain secure, sterile, and efficient, allowing them to focus on what they do best: innovating and producing high-quality products.

Whether you are upgrading your current cleanroom or designing a new facility, consider the benefits of Jamoclean sliding doors. With Jamison Door Company’s commitment to quality and innovation, you can trust that your cleanroom will meet the highest standards.