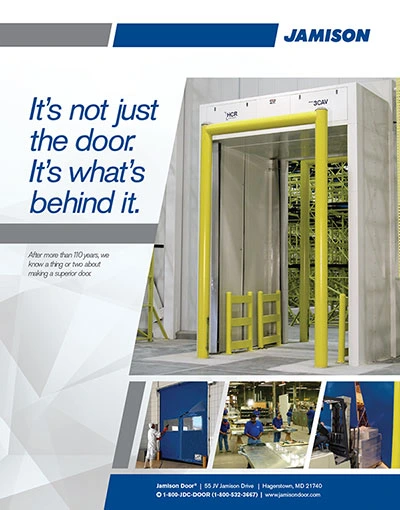

Mark IV® Bi-Parting Horizontal Sliding Power Operated Door

Jamison’s most popular door offers unique designs, features and benefits that keep it in high demand throughout the industry.

Our standard door panels and face casings are woodless.

Door Features

Available in Fiberglass

Constructed of Fiberglass for use in harsh environments such as food processing. Contact factory for more information.

Bi-Parting Power Fiberglass

Single Manual Fiberglass Track Door

Single Manual Fiberglass

Cooler Door Specifications:

Supply where indicated on plans Jamison Mark IV® Power Operated Bi Parting Horizontal Sliding Cooler Door, with Diamond-Trac® System* and PowerTron® Operator.

Door leaves to have aluminum extruded structure and to be metal clad with #26 gauge white pre-painted stucco embossed steel front and back. Frame (casings and header) to be constructed of aircraft quality aluminum extrusions with white painted finish.

Door leaves to be filled with 4″ of Jamifoam non-CFC polyurethane insulation with an R value of 28 at 40°F. Frame to be insulated with polystyrene inserts.

Door leaves to be equipped with low profile pneumatic reversing edge, effective full height and full travel of door. Upon contact, door in closing cycle is instantly reversed to open position.

Adjustable gasket at sides and head of frame and reversing edges cover gasket to be polyester reinforced; door leaves to have sweep type sill gasket.

Hardware to have protective coating against corrosion. Automatic opening to be provided with two remote control, spring-cushioned, low voltage pull switches.

Door power to be 208, 240 or 480 volt AC, 60 Hertz, three phase. (ARCHITECT TO SPECIFY VOLTAGE.) PowerTron® power operator to have all gear drive, and all power controls to be fully enclosed in NEMA 1 control boxes. Visible signal light to show when motor is running. Complete door assembly to be ready for connection to power. (ARCHITECT TO DESIGNATE RESPONSIBILITY FOR FIELD WIRING.)

Freezer Door Specifications:

Freezer door specifications to be same as cooler door except for these substitutions and additions:

Supply where indicated on plans Jamison Mark IV®Power Operated Bi-Parting Horizontal Sliding Freezer Door with Diamond-Trac® System* and PowerTron® Operator.

Provide Frostop heater cables in top, sides, lead edges and bottom of door. Complete device to be assembled, ready for connection to 120 volt, 60 Hertz, single phase AC line.

Special Notes:

- Freezer Door is designed for installation in warm room with temperatures plus 33°F. and above. If door must be mounted in rooms with temperatures of +32°F. and below, contact factory.

- When cold room temperature is below -20°F. and /or the relative humidity is greater than 80% on the warm side, Frostop heater cables should be added to the frame/gasket assembly.

- If the cold room temperature is below -40°F., or if the temperature difference exceeds 90°F., contact factory.

Product Overview

- Extruded aluminum door frame provides strength superior to wood.

- Designed to handle applications up to a 100F delta T.

- Extremely versitle with many options.

- Standard panels are white, stucco-embossed #26 gauge galvanized steel, front and back.

- Reversing edge is included with built-in sensing switch.

- Tear resistant adjustable frame gaskets.

- 5-year limited warranty.

Options & Accessories

- Metal cladding can be stainless steel, stucco aluminum, galvanized stucco embossed, galvanized, or galvanized steel painted to meet specifications.

- Padlocking provisions on front or back of door with safety release on opposite side. (Specify which side with locking.) Safety release feature permits door hardware to be released, thus minimizing possibility of personnel being locked in room.

- 6″ of insulation for freezer door (R value 42).

- 36″ pedestrian opening with automatic closing.

- Electric eye or motion detector to protect door from truck passage.

- Radio control operation from lift truck, 1, 2, or 4 button.

- Power components for connection to 120 volt AC 60 Hertz, single phase.

- Swinging wicket door.

- Complete NEMA 3, 4, 4X, or 12 requirements.

- Electrical reversing edge.

- Dual Speed Operator

- Hydraulic operator

- M.I.D. Requirements

- View windows: (contact factory for specific recommendations.) 12″ x 14″ sealed glass unit.

- Cooler Door – 2 layer 1″ thick

- Freezer Door – 3 layer, 1″ thick with 120 V.A.C. heat film.

- Jambs.

- Inside trim.

- Mirror image frame.

- Floor loop.

- Push button operation, single or three button (open – close – stop).