Are you looking to optimize your facility’s climate control, energy efficiency, and overall operational performance? Explore Jamison’s innovative Air Door solutions designed to revolutionize the way you manage airflow and temperature within your space.

What is an Air Door?

An air door, also referred to as an air curtain, is a specialized device installed over entrances to create an effective barrier of controlled airflow. Ideal for both industrial and commercial settings, air doors enhance energy efficiency by preventing the exchange of indoor and outdoor air. They contribute to optimal climate control, reducing temperature variations and minimizing the infiltration of dust, pollutants, and insects.

Jamison Door Company designs, manufactures, and installs various types of air doors.

AC Air Curtain

Model AC is HCR’s basic unit — Horizontal, Curvilinear, and Recirculatory. Its air stream produces counter-flow forces equal and opposite to the two-way flow-through forces caused by air temperature differences.

The Model CAC Air Curtain

The Model CAC Air Curtain is for applications where temperatures and humidity exceed the limits of our Model AC. A heater unit is added to condition the air as it mixes inside the vestibule.

The Model CAC automatically adjusts as conditions change to optimize performance and reduce energy consumption.

With the use of HCR sensors and software, Model CAC can be integrated into a facility’s refrigeration control and monitoring system. This allows not only remote monitoring but remote adjusting of the HCR equipment.

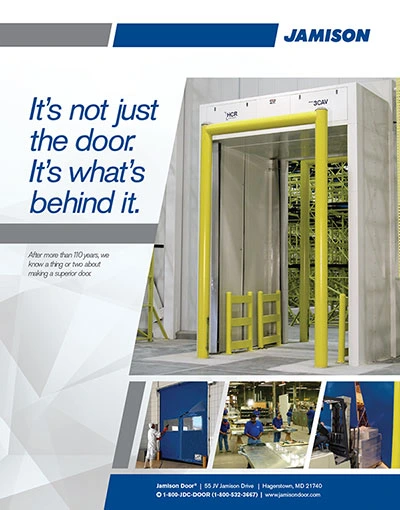

DCAV Double Conditioned Air Vestibule

The Model DCAV uses two recirculatory air curtains, creating an air vestibule between the two air streams where the air is captured and treated to a non-frost, non-fog state. The Model DCAV automatically adjusts as conditions change to optimize performance and reduce energy consumption. With the use of HCR sensors and software, Model DCAV can be integrated into a facility’s refrigeration control and monitoring system. This allows not only remote monitoring but remote adjusting of the HCR equipment.

3CAV Triple Conditioned Air Vestibule

The Model 3CAV is primarily used between rooms with extreme temperature differences and very high traffic. The frost elimination cycle is similar to the Model DCAV but the additional vestibule improves efficiency as well as increases the model’s temperature range applicability.

The Model 3CAV automatically adjusts as conditions change to optimize performance and reduce energy consumption. With the use of HCR sensors and software, Model 3CAV can be integrated into a facility’s refrigeration control and monitoring system. This allows both remote monitoring and remote adjusting of the HCR equipment.

Model NPAC Negative Pressure Air Curtain

The basic NPAC model is made to counteract the one-way flow-through forces caused by negative building pressure or by wind effects. Supply where indicated on plans HCR Model NPAC Air Door for doorways with low temperature differentials and or for temperatures above freezing. Air Door to be powder coated cold-rolled steel. Powder coating meets 500 hour salt spray test.

Hybrid: AC & CAC with VersaFlex®

Achieve the next level of efficiency by adding an HCR Model AC or CAC to your existing door. Perfect for high-traffic doorways where ice and infiltration are a challenge, an HCR Air Door provides another layer of protection to assure that the opening remains accessible for workflow, yet closed for costly air infiltration and energy efficiency.

Hybrid: AC & CAC with Roll-up Doors

By combining an air door with your currently installed door, you are assuring an efficient air block when your hard door is open, reducing cold air loss and decreasing the problems associated with high-traffic openings, such as ice and safety concerns.

Model RCAV Frost-Free Airlok Door

The Model RCAV is a short, conditioned-air vestibule for freezer to outer room conditions that span large temperature differentials up to 100 degrees with average doorway traffic and limited floor space around the door.

It significantly reduces refrigeration load while preventing frost, ice and wetness at the doorway. It consists of two high speed rollup doors, and a heated horizontal, recirculatory air curtain between the doors. It is equipped with a PLC or Solid State automated control, to regulate the amount of air and heat required.

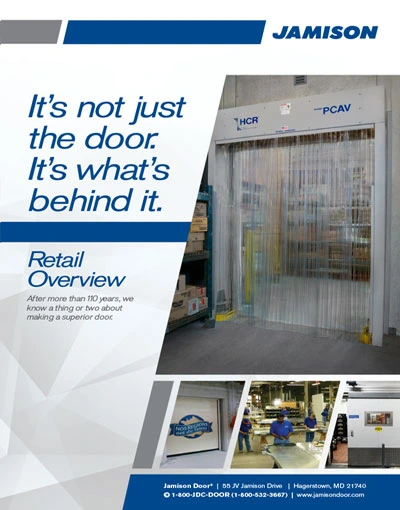

PCAV Push Thru Conditioned Air Vestibule

A conditioned air vestibule that uses a push-to-open versus a motorized opening. PCAV® consists of two pairs of impact-type doors or fixed strips, an electrically or hot-gas heated anti-frost air-conditioning (AFC) section with patent pending PLC control, and measures approximately 16 in the direction of travel.

MCAC Miniature Conditioned Air Curtain

Miniature/small version of CAC for conveyors. The temperature differences at conveyor openings, if unprotected, are subject to the same problems as regular doorways. Prevent air infiltration and frost and ice buildup by installing HCR equipment designed to work seamlessly with your conveyor system. Conveyor units are tailored to suit your specific application in coolers, freezers, or ambient temperatures. HCR project managers and engineers will discover every detail to assure the right solution for you.

Energy Efficiency and Cost Savings

HCR Air Doors significantly reduce the energy required to maintain cold storage temperatures by minimizing the loss of conditioned air. When these doors are in operation, they create a high-velocity air barrier that effectively separates different temperature zones, preventing warm air from entering cold storage areas and cold air from escaping. This efficient air barrier reduces the workload on refrigeration systems, leading to lower energy consumption. As a result, facilities can see substantial cost savings on energy bills, making air doors a cost-effective investment. Moreover, by conserving energy, these doors contribute to a greener, more sustainable operation, aligning with environmental goals and reducing the facility’s carbon footprint.

Enhanced Temperature Control

Our air doors create a seamless barrier that maintains consistent temperatures within your facility. This precise temperature control is especially crucial for environments that handle perishable goods, such as food processing plants and pharmaceutical storage areas. By preventing temperature fluctuations, HCR helps ensure that perishable products remain fresh and safe for consumption, extending their shelf life and reducing spoilage. Consistent temperature control also supports compliance with industry regulations and standards, ensuring that products meet quality and safety requirements. In addition, maintaining stable temperatures helps protect sensitive equipment and materials that may be affected by temperature variations, further enhancing the overall efficiency of your operations.

Superior Durability and Reliability

Built to withstand the demands of busy industrial environments, our air curtains are constructed from high-quality materials that ensure long-lasting performance. Their robust design includes components that are resistant to wear and tear, even in high-traffic areas where doors are frequently opened and closed. This durability minimizes the need for frequent maintenance and repairs, reducing downtime and maintenance costs. The reliability of HCR Air Doors means that they can consistently perform their function, providing uninterrupted protection for your cold storage areas. This dependable performance is crucial for maintaining operational efficiency and ensuring that temperature-sensitive products are always stored in optimal conditions.

Customizable Solutions

We understand that each facility has unique requirements, which is why our HCR Air Doors are fully customizable to fit specific operational needs. Customization options include various sizes to accommodate different door openings, ensuring a perfect fit for your facility. You can also choose from different mounting options to suit the layout and design of your space. Additionally, HCR offers a range of control features, such as variable speed settings and automated controls, allowing you to tailor the door’s operation to your specific needs. This level of customization ensures that you get a solution that not only meets your requirements but also enhances the overall efficiency and effectiveness of your cold storage management system.

Ease of Use

HCR Air Doors are designed with ease of use in mind, featuring simple installation processes and intuitive controls. Their user-friendly design means that they can be quickly integrated into your existing infrastructure with minimal disruption to your operations. The straightforward controls allow for easy operation, making it simple for staff to use the doors effectively. This ease of use ensures that your facility can start benefiting from the advantages of air curtains immediately after installation. Additionally, the low maintenance requirements of these doors mean that they will continue to perform efficiently with minimal upkeep, further contributing to the smooth operation of your cold storage areas.

Applications

Our air doors are found across a wide range of industries and applications:

- Cold Storage Facilities: Ideal for maintaining consistent temperatures in both refrigerated and freezer environments, ensuring optimal storage conditions for perishable goods.

- Food Processing Plants: Crucial for preventing contamination and maintaining hygiene standards by creating an effective barrier against external elements.

- Pharmaceutical Storage: Helps in maintaining the stringent temperature requirements necessary for storing sensitive medical products and pharmaceuticals.

- Distribution Centers: Enhances efficiency by reducing the energy loss associated with frequent door openings in high-traffic areas.

- Retail Grocery Stores: Useful in areas where there is a need to separate different temperature zones, such as between storage areas and retail floors.

- Industrial Facilities: Suitable for various industrial applications where temperature control and air quality are important.