In industries today, efficiency isn’t just a goal—it’s a necessity. As businesses strive to maximize durability and productivity, they also face challenges like maintaining hygiene, reducing downtime, and controlling energy costs. Jamison Door Company’s Jamotuf® fiberglass doors meet these challenges head-on, providing a solution that’s not only durable but also designed to enhance operational efficiency across industries.

Within the Jamotuf® line, we offer our Jamocor door and it’s stainless steel partner, our Jamoclean door. While people celebrate Jamotuf® doors for their toughness, they often overlook their broader benefits. Let’s explore how these doors go beyond durability to become an essential part of your facility’s success.

Effortless Maintenance for Continuous Operations

One of the key advantages of Jamotuf® doors is their smooth, gelcoat surface, which resists moisture, bacteria, and contaminants. This non-porous finish makes cleaning a breeze, even in industries with the strictest personal hygiene standards, such as food processing, healthcare, and pharmaceuticals. Traditional doors can trap contaminants in porous materials or hard-to-reach crevices, requiring extra cleaning efforts and longer downtime. In contrast, Jamotuf® doors are designed to simplify cleaning protocols and prevent the spread of germs.

With their ability to withstand frequent cleaning with industrial-grade chemicals, these doors also reduce the risk of wear and tear caused by harsh cleaning processes. This means fewer maintenance interruptions and more consistent operations, allowing your facility to focus on production rather than repair schedules.

Thermal Efficiency That Saves Energy and Money

Maintaining precise temperature control is critical for industries like cold storage, food and beverage production, and pharmaceuticals. Temperature fluctuations can compromise product quality and increase energy costs. Jamotuf® doors address this issue by offering exceptional thermal insulation options. By maintaining consistent internal temperatures, these doors help facilities optimize energy usage and cut down on heating or cooling costs.

In cold storage facilities, for example, the temperature differential between interior and exterior environments can be extreme. Jamotuf® doors minimize energy transfer, preventing costly temperature leaks. Over time, these energy savings contribute to a lower carbon footprint and a more sustainable operation. For businesses looking to meet sustainability goals while keeping energy costs in check, Jamotuf® doors are a perfect match.

Custom Solutions for Unique Challenges

Every facility has its own set of challenges, and one-size-fits-all solutions often fall short. Jamotuf® doors offer customizable configurations to meet the specific needs of your operation. Whether you require a door that accommodates oversized machinery, a high-traffic entryway, or specialized features for wet environments, Jamotuf® doors can be tailored to fit.

Customizable features include door size, thickness, color, and hardware options. For facilities prioritizing aesthetics alongside functionality, the doors can even be color-matched to complement the workspace. This flexibility allows businesses to optimize their workflows while maintaining a professional appearance. Furthermore, the design options extend to specialized features like windows, kick plates, and seals, ensuring every need is met without compromise.

Durability That Lowers Total Cost of Ownership

The durability of Jamotuf® doors is a well-known feature, but its financial implications deserve greater attention. Built to withstand heavy impacts, corrosive environments, and frequent use, Jamotuf® doors are a long-lasting investment. Facilities prone to harsh conditions, such as industrial manufacturing or wastewater treatment plants, will appreciate their resistance to rust, chemicals, and dents.

This toughness translates to fewer repairs, replacements, and associated costs over the lifespan of the door. Businesses often overlook the cumulative savings that durable equipment provides, but these savings can significantly offset the initial investment. For companies looking to future-proof their facilities, Jamotuf® doors are an excellent cost-effective choice that pays for itself over time.

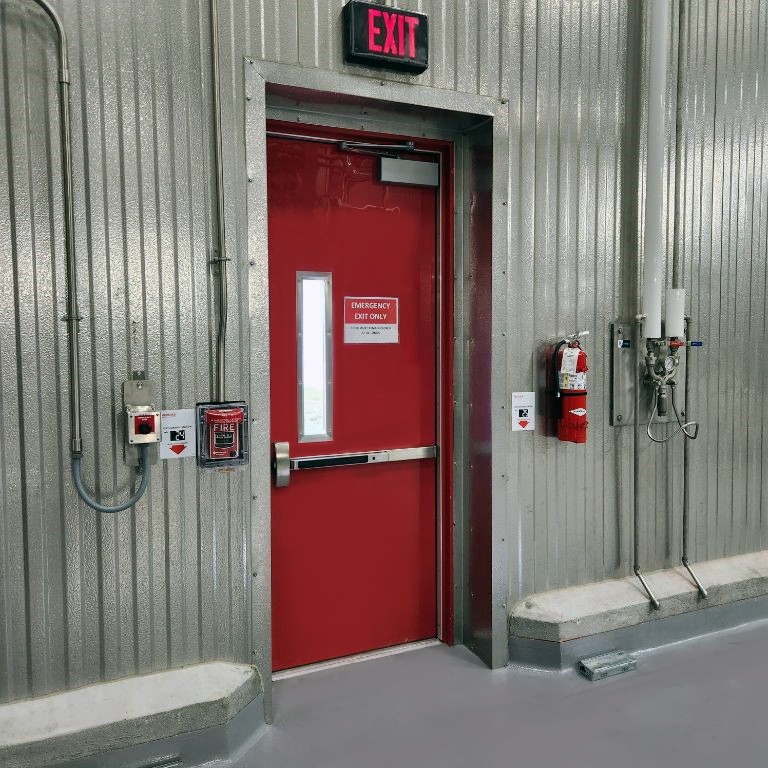

Supporting Safety and Compliance

Safety is non-negotiable in any industrial setting. Jamotuf® doors are designed with safety in mind, offering features that help facilities maintain compliance with industry regulations. Their robust construction helps create secure barriers, controlling access to sensitive areas and minimizing cross-contamination in hygienic environments.

Additionally, the doors can be equipped with advanced hardware options, such as panic bars or fire-rated components, to meet specific safety requirements. Their resistance to fire, moisture, and chemicals further enhances workplace safety, ensuring a secure environment for both employees and products.

Reducing Environmental Impact

Sustainability is becoming a priority for businesses across all industries, and Jamotuf® doors contribute to this goal in multiple ways. Their long-lasting construction reduces the need for frequent replacements, which minimizes waste. Additionally, the energy efficiency provided by their thermal insulation lowers overall energy consumption, reducing greenhouse gas emissions.

Jamison Door Company is also committed to responsible manufacturing practices. By choosing Jamotuf® doors, businesses align themselves with a product that supports both operational efficiency and environmental stewardship.

Applications Across Industries

Jamotuf® doors excel in a wide range of industries, each with its unique challenges:

- Food and Beverage: Provides hygienic, easy-to-clean solutions that prevent contamination during processing.

- Healthcare and Pharmaceuticals: Offers seamless surfaces and thermal control to support stringent cleanliness standards.

- Industrial Manufacturing: Stands up to heavy impacts, chemicals, and high traffic in demanding environments.

- Cold Storage: Ensures thermal efficiency to maintain product integrity and reduce energy costs.

- Wastewater Treatment: Resists corrosion and moisture, providing a long-lasting solution for harsh environments.

Conclusion: A Strategic Asset for Efficiency

Jamotuf® doors are much more than an entryway—they are a strategic asset that enhances your facility’s efficiency, safety, and sustainability. From simplified maintenance and energy savings to customizable designs and unmatched durability, these doors provide tangible benefits that extend far beyond their initial installation. Whether you’re looking to improve operations in a food processing plant, a pharmaceutical facility, or a manufacturing site, Jamotuf® doors are an investment in long-term success.

By choosing Jamotuf® doors, you’re not just adding a product to your facility—you’re investing in a solution designed to optimize your operations and support your goals for years to come. Explore the possibilities and see how Jamotuf® doors can transform your workspace into a model of efficiency and reliability.