Selecting the right door system is essential for optimizing energy efficiency, maintaining temperature control, and ensuring smooth operations in retail operations. Whether you’re managing a grocery store, convenience store, or large retail warehouse, having the right door solution enhances both workflow and customer experience.

Jamison Door Company offers a variety of solutions tailored to meet the diverse needs of the retail industry. From refrigerated areas to high-traffic entry points, Jamison has a door to fit every requirement. Let’s explore the best options for retail spaces and how they can enhance performance and customer experience.

Jamison Cold Storage Doors – All-Purpose Retail Solutions

For retailers who need superior insulation and durability, Jamison Plyfoam and Mark IV doors provide excellent solutions.

- Plyfoam – These doors feature high-density foam insulation, making them ideal for cold storage and refrigerated areas. They offer superior thermal performance and help reduce energy costs.

- Mark IV – This versatile line includes single, bi-parting, horizontal, and vertical sliding options, with both manual and power operation available. The VersaFlex variant provides additional flexibility, adapting to various retail storage needs. Additionally, the Diamond-Trac System ensures smooth and reliable operation, reducing wear and extending the life of the door.

- Retail Pro – The all-purpose retail solution. For retailers seeking a dependable, insulated door for coolers, freezers, and other temperature-controlled spaces, the Jamison Retail Pro is an excellent choice. Designed specifically for the retail industry, this door provides reliable thermal protection while allowing easy access for employees and stocking teams. It helps retailers maintain food safety standards and minimize energy loss, ensuring cold storage areas remain at optimal temperatures.

Jamison’s cold storage options provide durability and efficiency, ensuring that refrigerated goods stay at optimal temperatures while maintaining smooth retail operations.

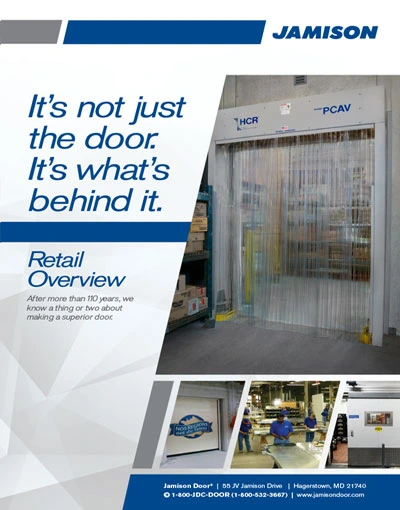

Jamison HCR Air Doors – The Ultimate Climate Control Solution

For retailers dealing with temperature-sensitive products and high-traffic areas, HCR Air Doors provide an innovative alternative to traditional swinging or sliding doors. These doors use high-velocity airflow to create an invisible barrier between different temperature zones, minimizing energy loss and improving workflow efficiency.

Key models for retail applications include:

- AC Air Curtain– Ideal for open doorways in supermarkets and retail stores, this air curtain prevents cold air from escaping while allowing unimpeded access.

- CAC Air Curtain – Specifically designed for refrigerated spaces, this model helps maintain optimal temperatures while allowing frequent access.

- DCAV Air Vestibule – A unique solution that combines two air curtains to separate different climate zones effectively, reducing frost buildup and condensation in refrigerated areas.

- Hybrid Doors – These combine traditional doors with air curtain technology, offering the benefits of both physical separation and airflow management. Hybrid doors are ideal for high-traffic areas requiring frequent access while maintaining strict temperature control.

HCR Air Doors enhance store efficiency by reducing energy consumption, keeping cold air contained, and improving employee workflow by eliminating physical door barriers. Cost savings are just an added bonus.

Jamison HPD High-Speed Doors – Fast, Efficient, and Durable

Retail environments demand doors that can handle frequent use while maintaining durability and efficiency. Jamison HPD (High-Performance Doors) offer high-speed roll-up doors designed to optimize movement within retail spaces, especially in backroom storage and receiving areas.

Notable models include:

- DynamicRoll – A flexible, self-repairing roll-up door ideal for high-traffic environments. It’s perfect for separating storage areas from sales floors without slowing down operations.

- Frigo 2 – Designed for freezers and cold storage areas, the Frigo 2 maintains insulation while allowing rapid movement of employees and stock carts.

Both of these doors contribute to operational efficiency by reducing downtime and ensuring quick and easy access to key areas within a retail store.

Which Retail Door Is Right for Your Business?

Choosing the best retail door depends on several factors:

- Temperature Control Needs – If your store has cold storage areas, the Retail Pro, Plyfoam, or Frigo 2 are great options. If you need an air barrier solution, the AC, CAC or DCAV might be the best fit.

- Traffic Levels – High-speed doors like DynamicRoll can handle frequent movement and self-repair if impacted.

- Energy Efficiency – To minimize energy loss, HCR Air Doors and Plyfoam doors help maintain climate zones without requiring physical barriers.

- Space Constraints – Sliding doors like Mark IV or air doors take up less space than traditional hinged doors, making them ideal for compact retail environments.

Final Thoughts

The right door solution can make a significant difference in a retail store’s efficiency, energy savings, and overall customer experience. Whether it’s the insulated Retail Pro, the innovative HCR Air Doors, the high-speed HPD DynamicRoll, or the durable Plyfoam and Mark IV doors, Jamison Door Company offers solutions tailored to the retail industry’s unique demands. By selecting the right door for your space, you can enhance efficiency, reduce energy costs, and create a seamless shopping experience for both employees and customers.

Looking for guidance on selecting the perfect door for your retail space? Contact Jamison Door Company today to explore your options and find the ideal solution for your business.