Cold storage doors are essential for preserving the quality of perishable goods. They help extend the shelf life of food, pharmaceuticals, and certain chemicals. Maintaining optimal temperatures is essential to prevent spoilage, contamination, and ensure safety.

Frequent movement of products in and out of cold storage facilities necessitates openings. These openings challenge maintaining a stable internal environment. Cold storage doors address these challenges. They ensure temperature control while allowing easy access.

Jamison Door Company designs, manufactures, and installs various types of cold storage doors.

Mark IV® VersaFlex® Bi-Parting Power Operated Door

The VersaFlex® was specially-designed with every component being a part of the hittable process. Using Jamison’s patent-pending Shearflow™ technology, panels are constructed with internal layers that move independently when struck. The Shearflow design reduces its normal rigidity by 75%, yielding to the impact, without damaging the panel or door components.

Mark IV® Bi-Parting Horizontal Sliding Power Operated Door

Jamison’s most popular door offers unique designs, features and benefits that keep it in high demand throughout the industry.

Our standard door panels and face casings are woodless.

Mark IV® Overhead Manually Operated Door Standard Lift

A favorite of industry experts, Jamison’s Vertical Sliders are extremely versatile with design configurations for virtually any application. Design Excellence: These doors are equipped with a unique “down-and-in” joggle track system that assumes friction-free operation until the last few inches of travel in the closing cycle. Additionally, our vertical and overhead doors employ an automatic locking top latch and counter-balance system for secure, finger-tip operation.

Mark IV® Bi-Parting Horizontal Sliding Manually Operated Door

Jamison’s most popular door offers unique designs, features and benefits that keep it in high demand throughout the industry.

Our standard door panels and face frames are woodless.

Mark IV® Vertical Lift Manually Operated Door

A favorite of industry experts, Jamison’s Vertical Sliders are extremely versatile with design configurations for virtually any application.

Mark IV® Food Pro® Stainless Steel Cooler and Freezer Door

With a Powertron® DS Operator, the Food Pro® opens a 40” single-leaf door in just one second. A double-leaf door opens 80” a second. Its incredibly smooth and quiet operation is unmatched in the industry.

Our standard door panels and face casings are woodless.

Mark IV® Overhead Manually Operated Door Standard Lift

A favorite of industry experts, Jamison’s Overhead Sliders are extremely versatile with design configurations for virtually any application.

Mark IV® Single Leaf Horizontal Sliding Manually Operated Door

Jamison’s most popular door offers unique designs, features and benefits that keep it in high demand throughout the industry. Our standard door panel and face casing are woodless.

Mark IV® Vertical Sliding Package Passing Door

A favorite of industry experts, Jamison’s Vertical Sliders are extremely versatile with design configurations for virtually any application.

Mark IV® VersaFlex® Single Leaf Power Operated Door

The VersaFlex® was specially-designed with every component being a part of the hittable process. Using Jamison’s patent-pending Shearflow™ technology, panels are constructed with internal layers that move independently when struck. The Shearflow design reduces its normal rigidity by 75%, yielding to the impact, without damaging the panel or door components.

Mark IV® Single Leaf Horizontal Sliding Power Operated Door

Jamison’s most popular door offers unique designs, features and benefits that keep it in high demand throughout the industry. Our standard door panels and face casings are woodless.

Plyfoam® I Swing Doors

Plyfoam® Doors are reliable, durable, tight sealing, easy-to-install and can be ordered in a wide array of sizes, styles, and options.

Plyfoam® II Swing Doors

The Plyfoam®II cooler and freezer door model has set the standard in swinging doors. Frame is flush with the floor line, meaning there is no sill to embed in concrete. Self-rising hinges actually lift the door when opened, reducing gasket wear and eliminating the need for sloped floors. The sweep-type sill gasket also prevents thermal infiltration.

Plyfoam®II Doors are reliable, durable, tight sealing, easy-to-install and can be ordered in a wide array of styles and options.

Plyfoam® Swing Package Passing Doors

The Plyfoam® II cooler and freezer door model has set the standard in swinging doors. Frame is flush with the floor line, meaning there is no sill to embed in concrete. Self-rising hinges actually lift the door when opened, reducing gasket wear and eliminating the need for sloped floors. The sweep-type sill gasket also prevents thermal infiltration.

Retail Pro™ Single Leaf Manually Operated Horizontal Sliding Door

Designed specifically for the needs of the retail industry.

Plyfoam® II Swing Doors

The Plyfoam®II cooler and freezer door model has set the standard in swinging doors. Frame is flush with the floor line, meaning there is no sill to embed in concrete. Self-rising hinges actually lift the door when opened, reducing gasket wear and eliminating the need for sloped floors. The sweep-type sill gasket also prevents thermal infiltration.

Plyfoam®II Doors are reliable, durable, tight sealing, easy-to-install and can be ordered in a wide array of styles and options.

Power Retail Smart Door

Smart Automatic Cooler and Freezer Doors bring down operating costs by making the doors ‘smarter’. Tests have shown that by the use of the Smart Controller, doorways are no longer being left open by employees thus enabling maximum energy savings, reduced infiltration, and improved productivity.

Plyfoam® Swing Double Doors

The Plyfoam® II cooler and freezer door model has set the standard in swinging doors. Frame is flush with the floor line, meaning there is no sill to embed in concrete. Self-rising hinges actually lift the door when opened, reducing gasket wear and eliminating the need for sloped floors. The sweep-type sill gasket also prevents thermal infiltration.

Plyfoam® Swinging Track Doors

The Plyfoam® II cooler and freezer door model has set the standard in swinging doors. Frame is flush with the floor line, meaning there is no sill to embed in concrete. Self-rising hinges actually lift the door when opened, reducing gasket wear and eliminating the need for sloped floors. The sweep-type sill gasket also prevents thermal infiltration.

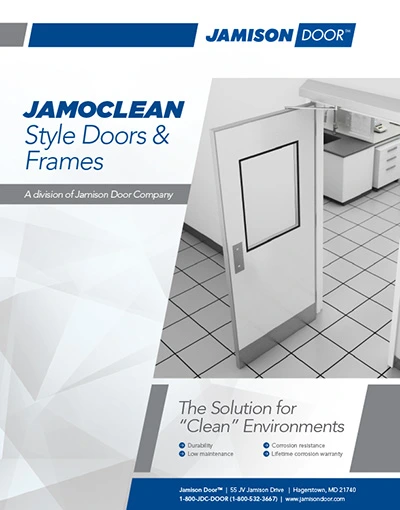

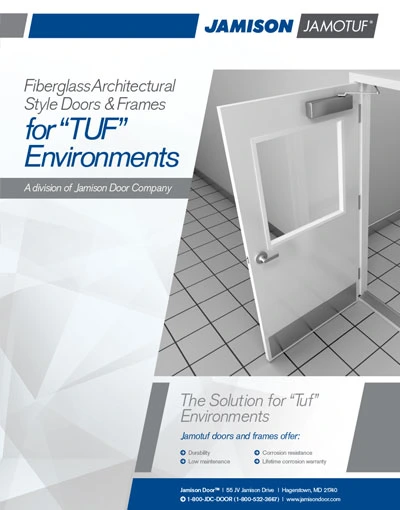

JAMOCLEAN® Stainless Steel Architectural Style 1.75″ Swing Door

‘Tuf’ and Beautiful. The Jamotuf® product line is the perfect combination of form and function.

Jamoclear® Swinging See-Thru Plastic Cooler Door

Swinging see-thru plastic cooler door. Door panel to be constructed of 1″ thick clear, transparent cast acrylic, Type #1 Grade A in accordance with Federal Specification L-P-391C. Bottom of door to be protected on front and back with #16 gauge stainless steel toe plates. Frame to be metal clad on all exposed surfaces with #24 gauge stainless steel…

Jamolite II Molded Fiberglass Swing Door

Doors offer the sleek, efficient, rugged design that is sometimes a major consideration when selecting the perfect door.

The Challenges in Cold Storage

Maintaining the integrity of a cold storage environment involves managing several challenges:

- Convection: Transfer of heat through air movement, raising internal temperatures and compromising stored products’ quality. Effective cold storage doors minimize warm air ingress during openings.

- Conduction: Direct transfer of heat through materials. Poorly insulated cold room doors and freezer doors let heat into the storage area. This increases energy consumption and jeopardizes stored goods.

- Infiltration: This involves the unintended leakage of air through gaps or openings. Unintended air leakage through gaps or openings, causing temperature fluctuations and condensation issues. Properly sealed cold storage doors, such as cold storage sliding doors and cold room hinged doors, are essential to prevent infiltration.

Types of Cold Storage Doors

Various types of doors are used in cold storage facilities, each designed to meet specific needs and operational requirements:

- Swing Doors: Common in small to medium-sized facilities. You can easily operate these cold doors and insulate them to reduce conduction.

- Sliding Doors: Suitable for larger openings. Cold storage sliding doors provide a space-efficient solution and can automate for frequent use.

- High-Speed Doors: These doors are ideal for high-traffic areas where quick access is required. The cold storage roll up doors open and close rapidly, minimizing air exchange and reducing energy loss.

- Air curtains: Create an invisible air barrier to prevent temperature loss and contamination when doors are open. Cost-effective and useful in high foot traffic environments, allowing frequent door openings without compromising controlled temperatures.

Cold Rooms vs. Freezer Environments

Cold rooms and freezer environments serve different purposes and require specific temperature controls:

- Cold Rooms: Maintain temperatures between 0°C and 10°C. They use them to store items like fruits, milk, and medicine that can go bad in cool temperatures but not freezing. Cold room doors are crucial for these environments.

- Freezer Environments: Maintain temperatures below 0°C, often as low as -18°C, to preserve frozen foods and ice cream. Warehouse freezer doors efficiently maintain these low temperatures.

Benefits of Cold Storage Doors

Cold storage doors offer numerous benefits that enhance the efficiency and effectiveness of temperature-controlled environments. One of the primary advantages is energy efficiency. With advanced insulation and sealing technologies, these doors significantly reduce energy consumption, leading to considerable cost savings.

Enhanced temperature control is another key benefit of cold doors. These doors help maintain precise temperature settings, ensuring that products remain in optimal conditions.

High-quality cooler and freezer doors also improve the operational efficiency of facilities. Easy-to-operate doors, such as high-speed cold room doors and cold room swing doors, reduce downtime. They also streamline workflow, allowing for smoother operations.

Safety and compliance with industry standards are crucial in cold storage applications. Jamison’s doors meet rigorous requirements, ensuring that facilities adhere to health and safety regulations.

Environment and Applications

Cold storage doors are used across a wide range of industries and applications:

- Food and Beverage: From meat and dairy to fruits and vegetables, maintaining the freshness and safety of food products is paramount.

- Pharmaceuticals: Temperature-sensitive medications and vaccines require precise temperature control to remain effective.

- Chemical Storage: Certain chemicals must be stored at low temperatures to prevent degradation or reactions.

- Retail and Distribution Centers: Cold storage doors in supermarkets and distribution hubs ensure quick access while preserving product quality.

- Hospitality: Hotels and restaurants use cold storage to keep ingredients fresh and safe for consumption.

- Warehousing & Logistics: Enhance efficient handling and storage, maintaining optimal conditions for temperature-sensitive goods during transit and storage. This ensures quality preservation and timely delivery.